As we delve deeper into this field, further research becomes paramount to explore and harness the full capabilities of this aquatic plant. One area of investigation focuses on utilizing the high absorption capacity of water hyacinth to develop tiles that can effectively purify and clean polluted rivers, offering a sustainable solution to water contamination.

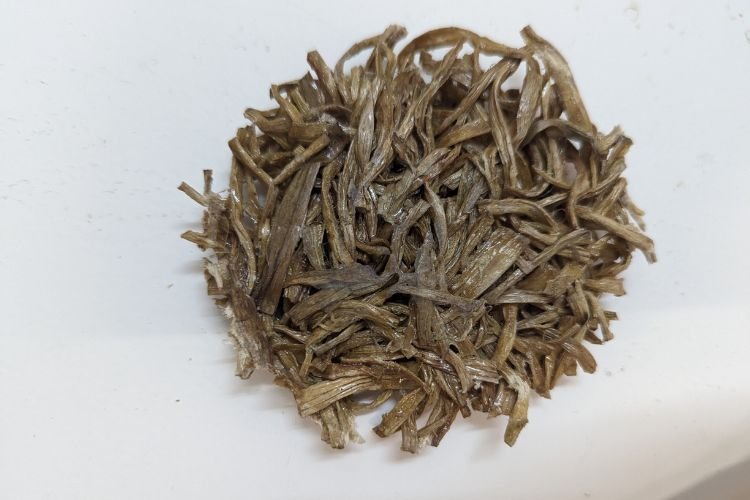

Moreover, the high cellulose content present in water hyacinth presents an opportunity to extract fibers that can be used in various applications. Further research aims to develop sustainable techniques for deriving cellulose from water hyacinth, unlocking its potential as a renewable resource for the production of textiles, papers, and other cellulose-based products.

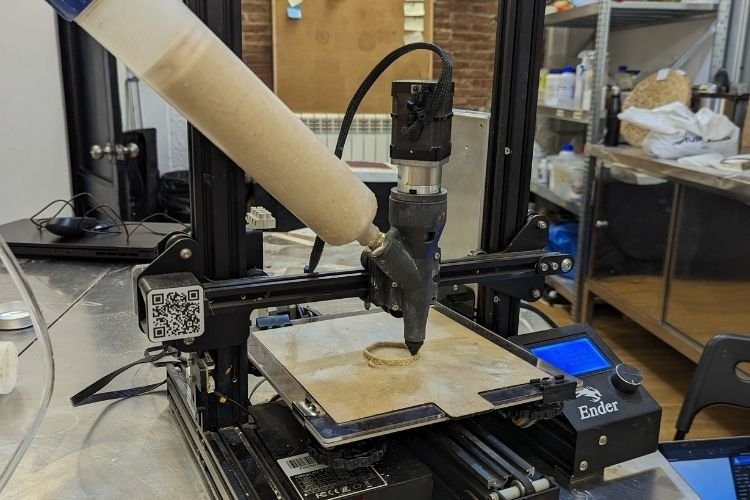

The pursuit of sustainable practices is a key aspect of ongoing research in the field of water hyacinth biomaterials. We are actively exploring environmentally friendly methods for harvesting, processing, and manufacturing, ensuring that the entire lifecycle of the biomaterials aligns with the principles of sustainability. By delving into these aspects, we strive to create biomaterials from water hyacinth that not only offer innovative solutions but also contribute to a greener and more sustainable future. Through continuous research and collaboration, we can uncover new insights and techniques that will propel the development of water hyacinth biomaterials towards greater success and positive environmental impact.